Shaping Excellence:

Your Aluminum Extrusion Solution

Encapsulates our commitment to providing superior quality and precision in aluminum extrusion processes, ensuring that we meet and exceed the unique needs and specifications of our clients with excellence and reliability.

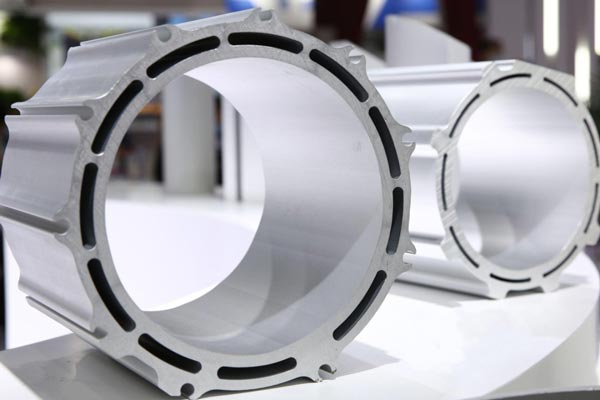

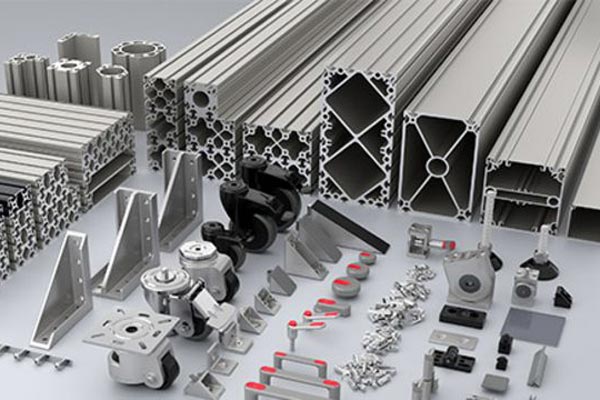

Your Aluminum Extrusion

Aluminum extrusion stands as a cornerstone process across numerous industries, driving innovation and efficiency in product development. Our bespoke aluminum extrusion services are meticulously tailored to align seamlessly with the unique demands of your company, encompassing everything from the precision extrusion of aluminum profiles to expertly applying surface finishes, intricate machining, precise cutting, and meticulous assembly.

How Does Aluminium Extrusion Work

Aluminum extrusion is a versatile manufacturing process that involves heating aluminum billets or logs to a specific temperature, typically between 800 to 900 degrees Fahrenheit, to make them malleable. Once heated, the aluminum is pushed through a shaped opening in a die using a hydraulic press or ram, resulting in the material taking on the desired form. This method allows for the creation of complex shapes and profiles with uniform cross-sections, making it ideal for a wide range of applications across industries such as construction, automotive, electronics, and more.

Benefits.

- Cost-effective and efficient

- Strong and lightweight

- Corrosion-resistant and resilient

- Wide range of sizes and shapes

Applications.

- Automotive

- Electronics

- Building and construction

- Consumer products

Talk To Us About Your Next Project

Finishing Options for Aluminium Extrusion

Finishing options for aluminum extrusion are methods of applying a protective or decorative layer to metal surfaces to enhance their appearance, durability, and functionality. Some common finishing options are:

Anodization: Anodizing is commonly used to improve corrosion resistance and wear resistance of aluminum parts. It can also provide other desirable benefits such as improved heat dissipation and the ability to accept dyes.

Powder coating: Powder coating is a suitable alternative to anodizing, giving excellent chemical resistance and tone consistency.

Painting: To change the color and surface appearance of an aluminum extrusion, painting is a good option. It can create different effects such as matte, gloss, or textured.

Mechanical finishes: Aluminum can be blasted, polished, grinded or sanded. These finishes can improve surface quality or prepare the aluminum for other cosmetic finishes.

Sublimation: After a base coat of powder, the profile can undergo sublimation. The sublimation process transfers that pattern directly onto the extrusions.

Mirror surface: In order to give the aluminum a specular or “mirror” finish, we need to put the profile into a special dip solution (a combination of hot phosphoric and nitric acids). Aluminium parts can also be anodized.

Beisi Rapid

Precision CNC machining allows designers, R&D teams, and manufacturers who rely on components supply to create complicated products without further machining.

Services

Contact Beisi

Address

Room 202, 2nd Floor, No. 53 Huanmao Road,

Xuecun, Torch Development Zone, Zhongshan City

Instant Call

+86 153 9880 0243